Test Stand Rollout

This is the fifth and final part in a series about UB SEDS rolling out a test stand to support our in-house propellant program. In this part we validate the test stand using a motor characterize by the manufacturer.

- Part 1 – Smoke Test

- Part 2 – Backboard Test

- Part 3 – Structural Test

- Part 4 – Electronics Test

- Part 5 – Final Check Out

If you just want to see the test stand page, you can find that here.

If you want to find out more about our propellant mixing, you can find that here.

If you have enjoyed this series and want to see more posts like this, or have a critique on how I can make future posts better let me know!

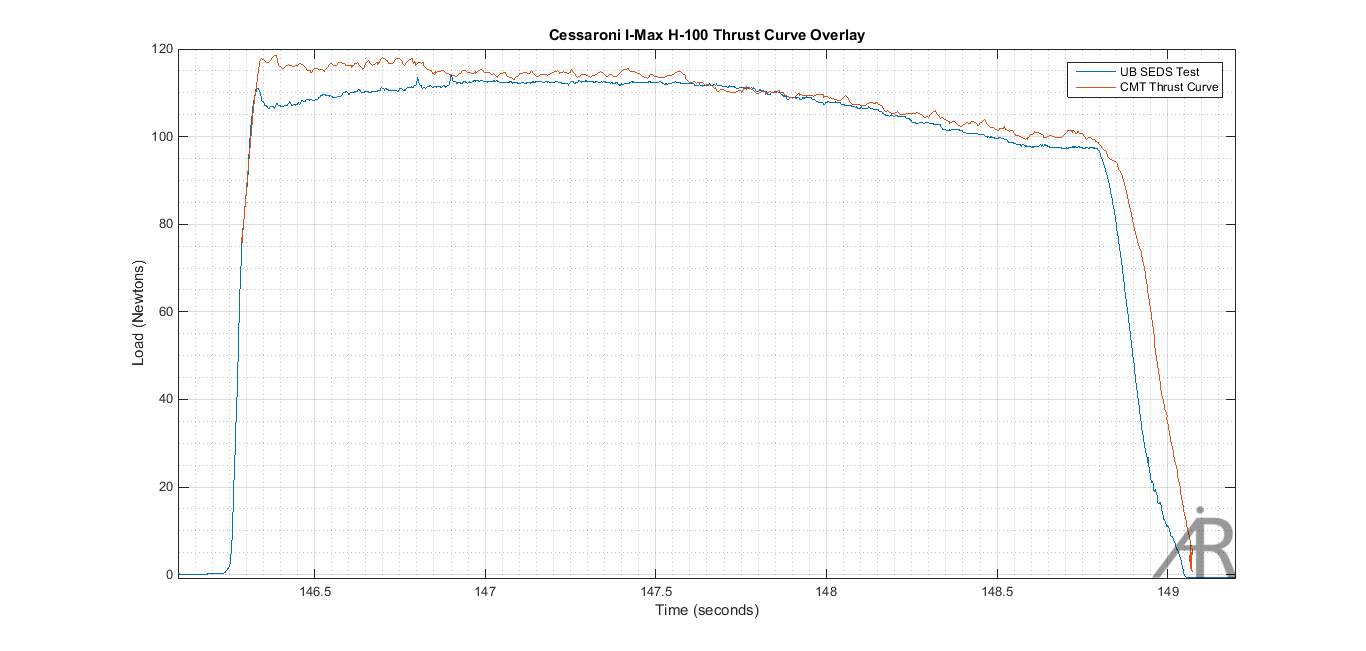

Test Plan

In order to verify that the thrust curve measured by the test stand is correct we need to burn an already characterized motor. Because motors are used up after each burn, we can’t re-burn an already characterize motor. We decided to test a Cessaroni 38mm I-Max H-100 (Pro38 286H100-15A) . The last time that Cessaroni characterized their motor was in 2009, which is 9 years before we tested our motor. Because of the amount of time between their testing and the purchase of our motor we feel confident that their test motor and our test motor are not from the same batch. Because of this difference, we were not expecting the thrust curve to be exactly the same. Instead, we expected the bulk stats to be extremely close, and the thrust curve to be similar. Additionally, their reported sampling frequency was 1000Hz while ours is around 600Hz.

Results

The test stand bulk results are shown below. CMT stands for Cessaroni Motor Technologies, the manufacturer of the motors.

| CMT Measurement | Our Measurement | Percent Difference | |

| Total Impulse (Newtons) | 286.40 | 282.49 | 1.3746 |

| Max Force (Newtons) | 117.90 | 114.07 | 3.3022 |

| Burn Time (Seconds) | 2.82 | 2.80 | 0.712 |

As we can see, the bulk stats are almost exactly the same, with 3 percent difference or less. These differences, can all be attributed to differences between batches.

Below, I’ve overlaid the two thrust curves. Our measured thrust curve is in blue, while CMT’s is in red. Through visual inspection, they are seen to be extremely similar. We feel confident that these differences are not due to the test stand, but instead to differences between the batches. The test stand has now shown that it can accurately measure the thrust curve from a rocket motor.

Note: In the link to the Cessaroni data sheet, we have an image of the thrust curve. I could not find a data set to match this curve so I used Web Plot Digitizer to convert the image into discrete points. Web Plot Digitizer is both an extremely helpful online application as well as free.

No Burn Pics from the Validation

Being in Buffalo, the weather tends to get cold. We ran this test when it was about 15° F (-9°C) outside. This was the coldest weather we had ever run a test in, and while we were prepared clothing wise, we weren’t prepared camera wise. When we began to set up for the test, we setup our camera and GoPro as normal. We left them setup as we finished preparing for the test. At these cold temperatures the batteries become unusable after a short time and we couldn’t take photos/videos of the test.

Since then I’ve started to keep the batteries in an interior pocket until just before we begin to test. This has solved our imaging problem but because of the weather I don’t have any images of this burn. Instead I have included a picture from a different test burn that I liked so much I am using it as my phones background. I may post this picture again if I end up writing a post about that burn.